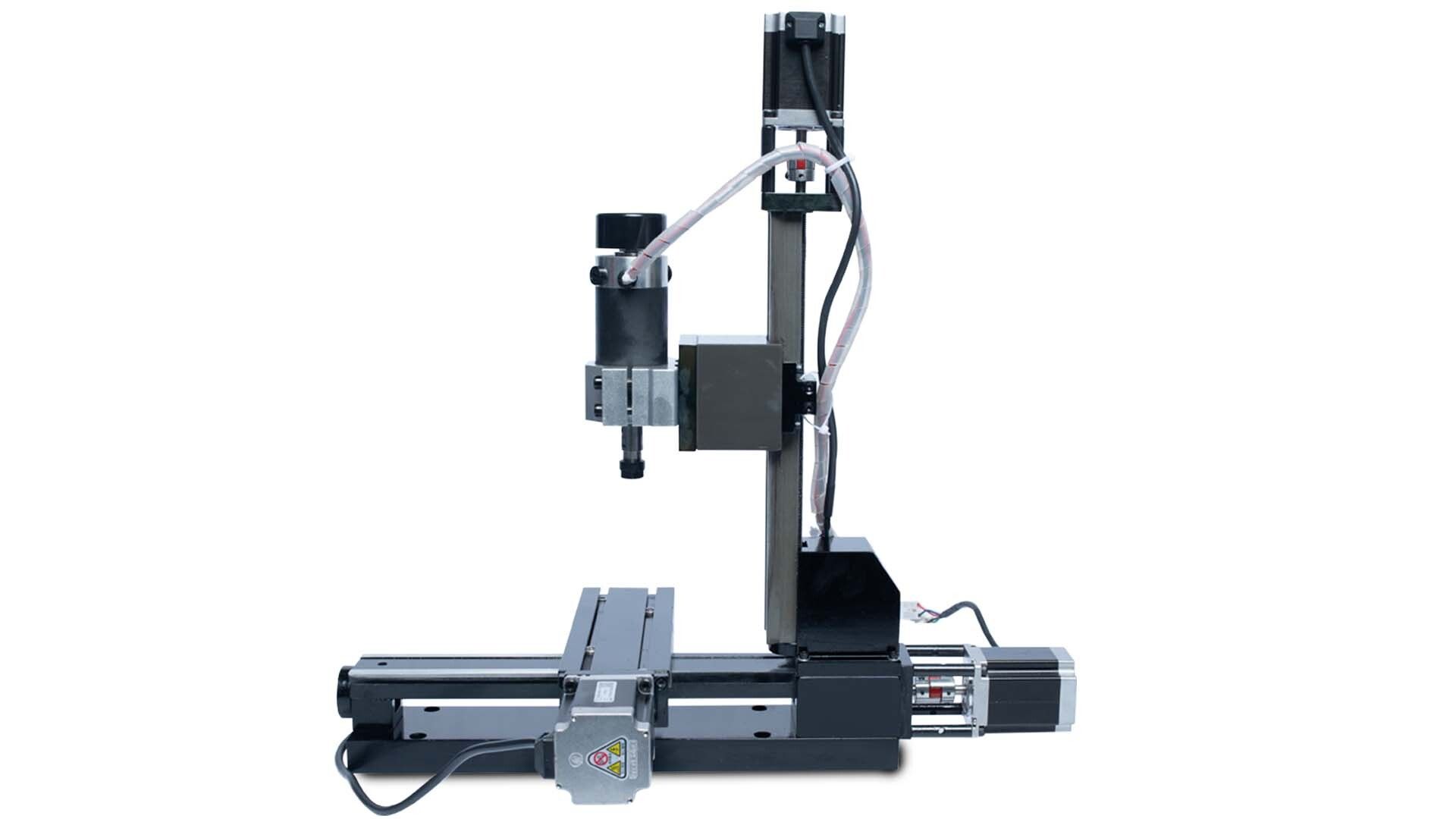

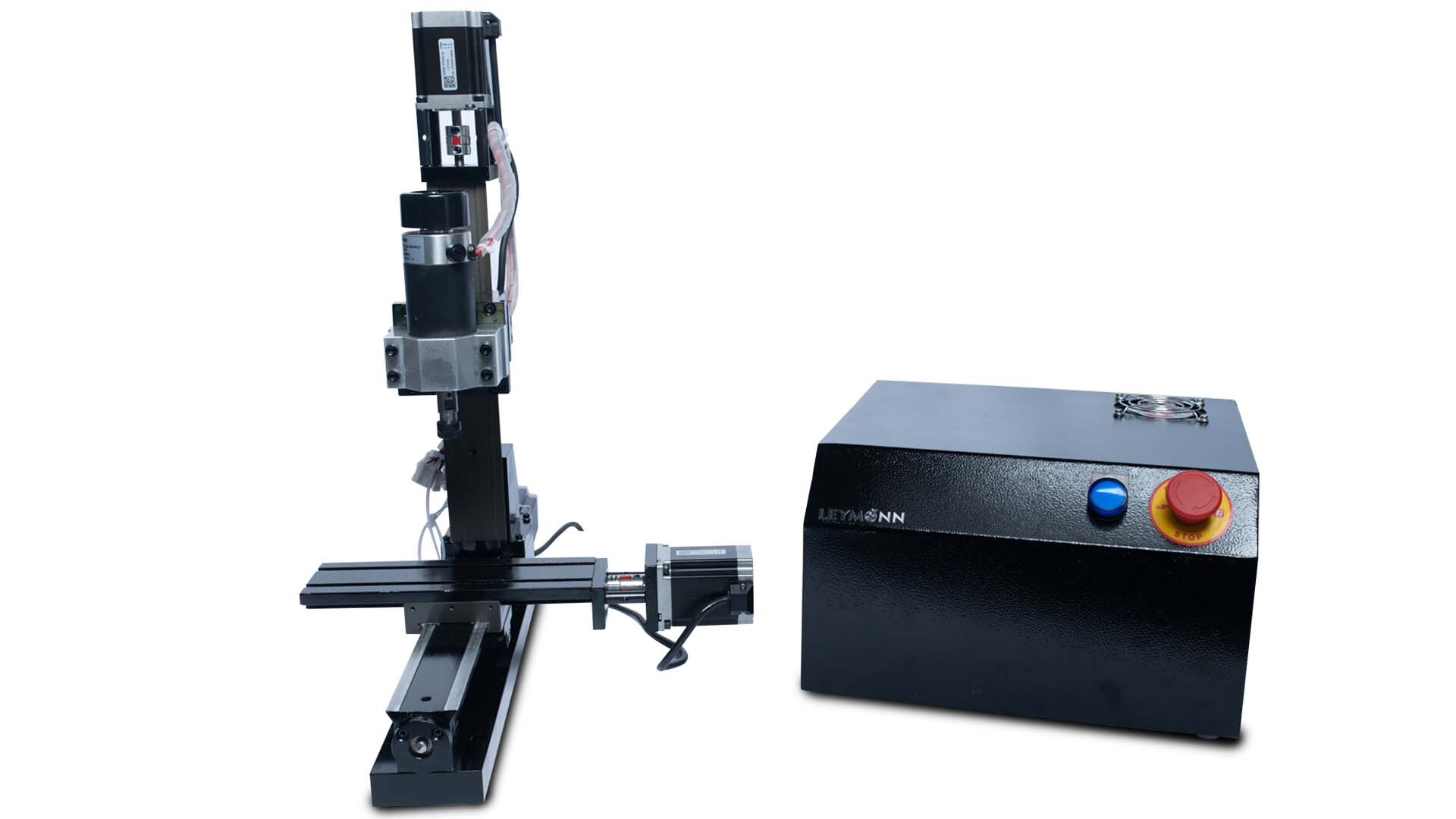

Table Top CNC Mill

Product Details:

Table Top CNC Mill Price And Quantity

- 1.20000 INR

- 1 Set

Table Top CNC Mill Trade Information

- as per oder Per Week

- 15 Days

Product Description

Ever since the formation of our company, we are indulged in manufacturing and supplying an excellence range of Table Top CNC Mill that is used to produce three-dimensional parts of a solid materials like wood, metals etc. This mill is manufactured in accordance with the set industrial norms and it is well tested at our well-developed production unit to ensure its flawlessness. Made from pristine quality components and cutting-edge technology, the offered Table Top CNC Mill is available with us in numerous technical specifications to satisfy clients diverse need.

Features:

-

Hassle-free operations

-

Low power consumption

-

Sturdy construction

-

Longer service life

Table Top CNC Mill

Specifications:

-

Compact and Light weight only 25 Kgs!

-

Perfect for small jobs machining.

-

PC based system

-

Proven and user friendly Mach3 interface.

-

Easy to operate. Even a school student can learn to operate the machine within an hour.

-

Spindle speeds infinitely variable from 100-3000 RPM.

-

Very easy Electronic spindle speed adjustment.

-

Suitable for ITIs, Engineering Colleges and all types of small and medium Engineering and Hobby Shops.

Standards:

-

Machine tool with three stepper motors on X, Y and Z axes

-

DC motor with speed control unit for spindle

Options:

-

Servo motors for all three axes and

-

AC motor with VFD

Machine Specification:

|

X Axis traverse |

240 mm |

|

Y Axis traverse |

150 mm |

|

Z Axis traverse |

200 mm |

|

Table Length with 'T' Slot |

220mm X 75mm |

|

Spindle Inside Taper |

8 Deg (for ER16 collet) |

|

Spinde Speed |

100-3000RPM Infinitely variable |

|

Cross Slide Inclination |

0 Degrees |

|

Cutting Tool |

Size 6x6 mm |

|

Spindle motor DC Motor |

1 HP DC Motor, 2HP DC Motor, 1 HP |

|

Automatic Lubricate *xr-Points Provided |

Optional |

|

Input System |

Metric/ Inch |

|

Control Axes |

Simultaneous axes |

|

Interpolation |

Linear, Circular, elliptical and Parabolic, Slot milling, Rectangular and circular slot milling |

|

Minimum increment |

0.005 mm |

|

Minimum Movement command -X |

0.005 mm |

|

Minimum movement command -Z |

0.005 mm |

|

Repeatability |

± 0.02 mm |

|

Rapid Feed Rate X & Y |

400 mm / min |

|

Rapid Feed Rate-Z |

800 mm / min |

|

Dwell (Seconds) |

Programmable |

|

Backlash compensation |

Provided |

|

Speed override |

40%-160% |

|

Feed override |

20%-120% |

|

Type of Control system |

PC based system |

|

Real Time Tool Path Simulation |

Provided |

|

General |

Parameters |

|

Floor Area |

600 x 600 X 600 mm |

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+